Why Is My Ice Machine Not Making Ice?

In a bustling hotel, cafe, or restaurant kitchen, everything hinges on timing; ice is not excluded. A consistent supply of ice keeps processes running and clients happy, whether it’s freezing beverages for visitors, preserving ingredients, or setting up seafood displays. But the interruption can be quick and expensive if your commercial ice maker suddenly stops producing.

Industry studies indicate that daily sales and food safety compliance can be affected by even a few hours of downtime from an ice machine. Considering how important these tools are, it’s critical to know why they may break—and more particularly, how to swiftly repair them.

The most typical causes your business ice machine is not producing ice will be discussed in this guide, along with troubleshooting advice and prevention of future failures.

Typical Causes Your Ice Maker Isn’t Making Ice

Difficulties in Power Supply

Always verify that your ice machine is properly hooked to a power source before going into mechanical issues. The unit’s whole operation can be stopped by a tripped circuit breaker, an unplugged cord, or a bad power switch.

Water Supply Issues

No water implies no ice. Make sure the water valve is open, hoses are securely connected, and there are no kinks in the line. Low water pressure or a clogged entrance could also stop good ice development.

Filter for Dirty Water

Over time, your ice machine’s water filter could get clogged with sediment or scale. A soiled filter reduces water flow, therefore causing inadequate or stopped ice production. Replace or wash the filter as per the manufacturer’s schedule.

High Ambient Temperatures

Commercial ice manufacturers perform best across a particular temperature range. Too hot of a room can cause the condenser to overheat or prevent the system from reaching freezing temperatures. Set the machine in a cold, well-ventilated space.

Coils of Dirt and Condenser

Grease and dust can build up on the condenser coils, therefore decreasing heat dissipation. This hampers the machine’s ability to freeze water and form ice. Regular coil cleaning will help to bring back effectiveness.

Slime Accumulation or Internal Scale

Unregularly cleaned ice machines can accumulate internal deposit of minerals, mold, or slime. Internal water flow can be obstructed by this or sensors may be disrupted, therefore terminating the ice-making cycle.

Malfunctioning Sensors or Thermostats

Internal sensors and thermostats help to control cycles in modern ice manufacturers. Should a temperature sensor malfunction or misread, it could indicate that the ice bin is full or the water is not cold enough—even if that is not the case.

Troubleshooting Process

Verify the Unit Is Connected and the Switch Is Enabled

Search for tripped circuit breakers or fuse boxes. Check the outlet with another device to ensure it works.

Look at the Water Supply

Fully open the valve for the water supply. Examine all water lines for kinks or obstructions. Check if the water pressure satisfies the machine’s minimum requirements using a pressure gauge.

Clean or Replace Your Water Filter

Find the water filter either within the access panel or close to the inlet valve. Under running water, remove the filter and wash it. Replace if it seems blocked or has not been updated in six months.

Purge the Condenser Coils

Usually on the back or bottom, unplug the unit and access the condenser area. Remove dirt and debris with a soft cloth or a vacuum cleaner with brush attachment. Should it be necessary, wipe it with a moist cloth and allow it to dry before switching on.

Change the Airflow and Arrangement

Away from heat sources like ovens or dishwashers, move the device. Make sure air circulation is at least 6 inches on all sides. If your unit has them, clean any external air filters.

Carry Out a Cleaning Cycle

Use a manufacturer-approved cleaning agent and the unit’s procedure for descaling or cleaning should be followed. Machines with one-touch cleaning capabilities can automate this stage but still call for hand cleaning of detachable components. After cleaning, always discard the first batch of ice.

Search for Error Codes

Search the display panel for any blinking lights or error messages. Consult the user handbook to decode these codes and follow the corrective actions.

Preventive Maintenance Tips

Regular Cleaning

Machines operating in busy or humid conditions might need monthly inspections.

Water Quality Monitoring

To minimize mineral and sediment accumulation, use filtered or softened water. One frequent reason for scaling, hard water can swiftly clog internal parts.

Organize Routine Inspections

Get at least once a year an expert technician’s examination of your machine. Before they develop into serious problems, preventative checkups can find worn-out components, refrigerant leaks, or deteriorating performance.

Clean Removable Elements

Remember to wipe the ice bin, scoop, water trough, and any detachable trays or protectors. These regions should be cleaned with food-safe sanitizers, as they could contain bacteria or odors.

Replace Filters on Schedule

Most commercial ice makers advise replacing the water filter every 6 months, or more often if you live in an area with poor water quality. A clean filter enhances ice quality as well as water flow.

When to Phone a Technician

Certain problems need expert servicing, particularly if the machine:

- Making startling or strange noises

- Frequently pauses mid-cycle

- Shows error codes you’re unable to clear

- Leaks water from inside the housing

- Creates hot or slushy ice

Problems with the Compressor or Refrigerant

Without training, trying to fix sealed parts, refrigerant lines, or circuit boards may damage warranty or cause more damage.

Final Words

Many times, basic elements such as high temperatures, blocked filters, or unclean coils are to blame. By examining every system—power, water, air, and internal components—you may solve many problems yourself without needing a service call.

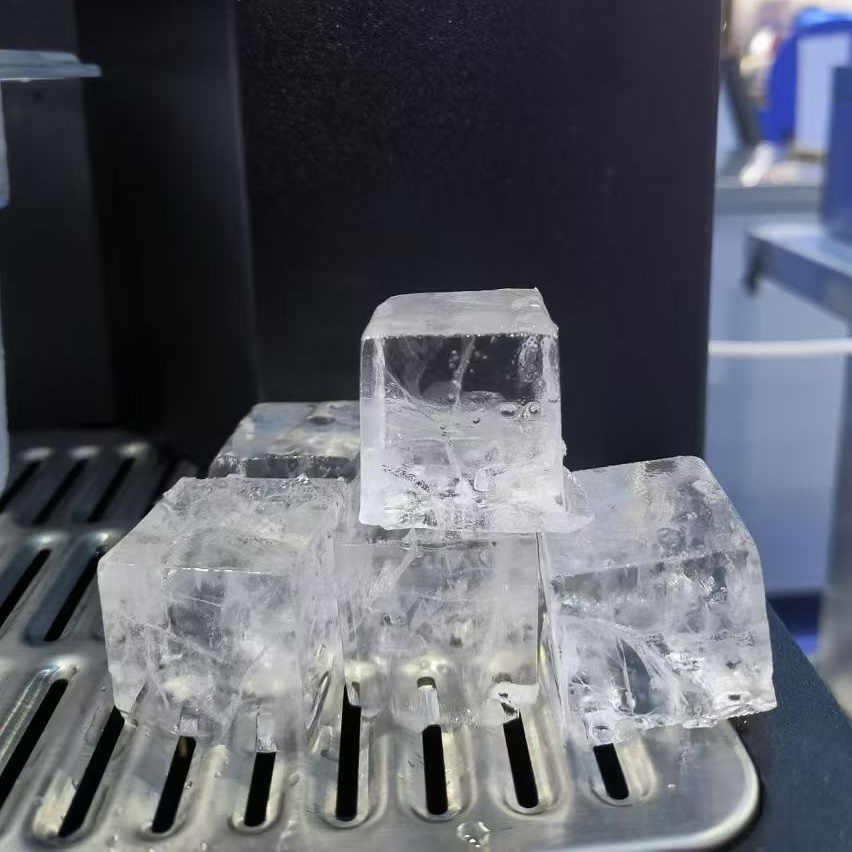

Always adhere to the manufacturer’s maintenance schedule for best results; regularly clean your unit; and address any performance problems early. This guarantees a consistent supply of pure, transparent ice and prolongs the life of your gear.

To save downtime and keep your company operating smoothly, if uncertain, seek advice from your user handbook or a certified technician.